Turbiwatt au pays du soleil levant

Projet réalisé en janvier 2021. Utilise deux Turbines T800 couplées à des armoires électriques Turbiboard, afin de produire 22 kW.

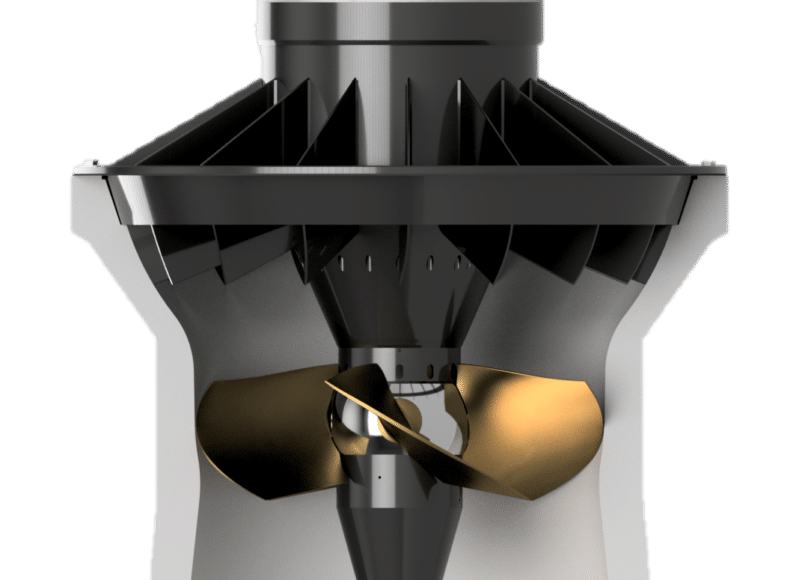

Kaplan bulb type with fixed hydraulic settings

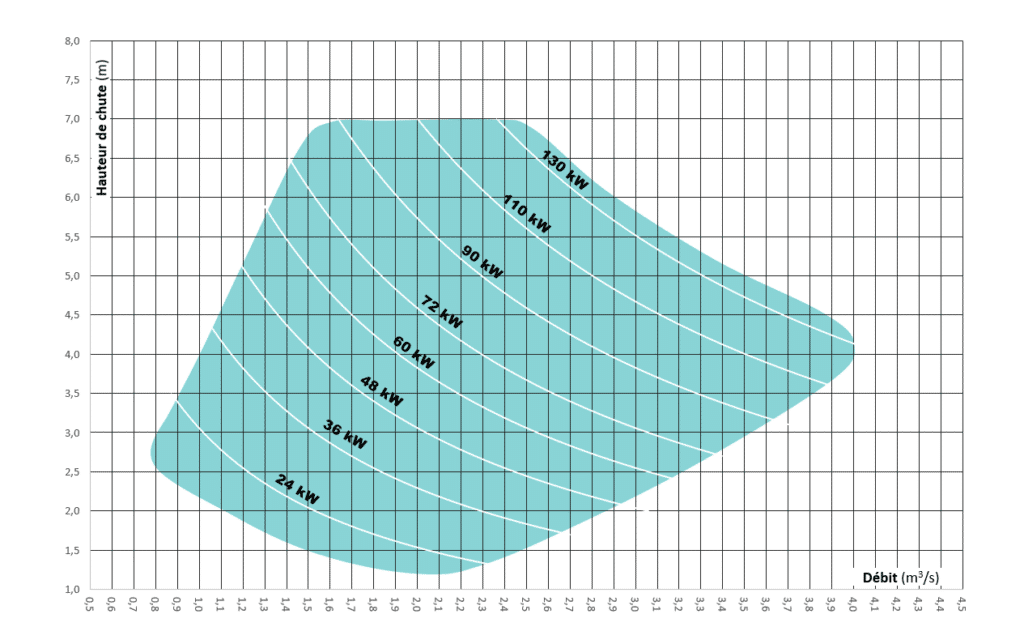

Rated power 24 to 130 kW depending on height and flow rate

Nominal flow rate from 700 l/s to 4000 l/s

Nominal head from 1,2 to 7,0 m

Integrated high-efficiency permanent magnet three-phase generator 400 V 50 Hz (60 Hz on request)

Ultra-compact, it can be integrated into existing environments or those to be renovated with great installation flexibility

Immersed, it is invisible and silent

Robust and long-lasting

Standardized, it allows profitability for your low head hydroelectric projects

Decarbonised by nature, it meets the current climate challenges

The head and flow rate define the available power for each project:

feffe

Always associated with its concrete suction cone (supplied with the turbine). Above a certain flow rate, a cone extension is necessary (optional)

To avoid air ingress, the cone and its extension must be completely immersed downstream under at least 30 cm of water

A screen and a suitable valve must be installed upstream of the turbine

The turbine must be placed in a water chamber of sufficient volume and must have a minimum head above it to avoid vortex phenomena

Several turbines with different power ratings can be installed in parallel to optimise seasonal flow variations

The turbine produces direct 400 V three-phase / 50 Hz (60 Hz optional) alternating current at the grid standards for the site characteristics (net head and flow rate) for which it has been defined

The energy produced is fed back to the grid via our control and coupling cabinet

The production of three-phase energy requires that the receiving installation is three-phase and balanced

Connection to the grid requires permits and/or contracts with the distributor according to national regulations and standards

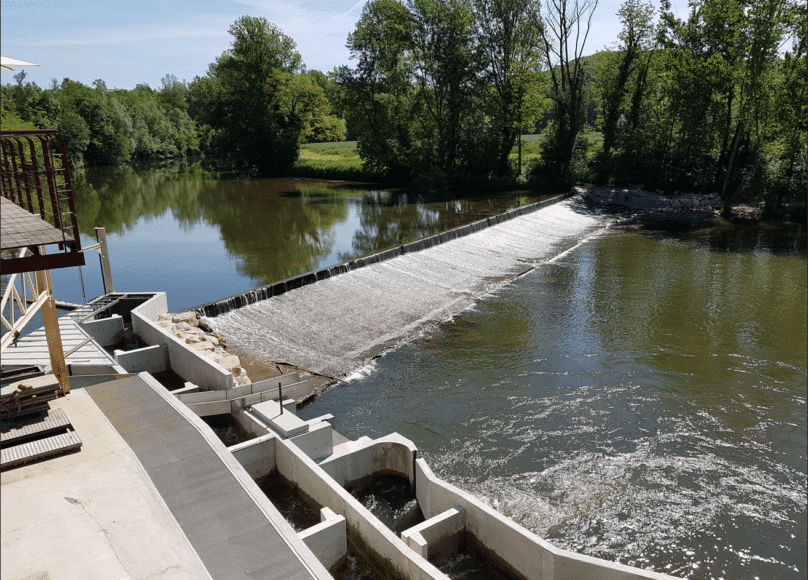

Case study

Project completed in June 2018. Uses a T1300 Turbine coupled to a turbiboard electrical cabinet, to exploit the dam’s attraction flow.

En savoir plus

Projet réalisé en janvier 2021. Utilise deux Turbines T800 couplées à des armoires électriques Turbiboard, afin de produire 22 kW.

Projet finalisé en octobre 2019. Turbines connectées à des armoires Turbiboard et reliées directement au réseau EDF.

Projet datant de mars 2018 pour l’équipement d’une turbine T800 de 14 kW intégrée à un barrage.